Powder Technology

C-Line Powder Compacting Presses

Whether for the automotive, aerospace, tooling or consumer goods industry: with LAUFFER powder presses you produce high-quality components.

Complex geometries in metal, hard metal or ceramics, which would otherwise have to be produced at great expense, can be produced economically, quickly and efficiently. LAUFFER offers the entire portfolio from laboratory presses for material testing purposes, presses for prototype and small series production to multi-plate presses with up to 13 axes or press lines for mass production.

Since Lauffer powder presses without mechanical fixed stops position all machine axes synchronously, automatic corrections of the press position during operation are possible, efficiently and without manual intervention.

Of course, efficient automation of powder presses is also part of our portfolio. With our specially developed CNC control system and our intelligent “powder assistant” for tool development, program sequence optimization and quality assurance, you can operate and monitor every pressing process conveniently, safely and reliably.

C-Line Powder Compacting Presses

Whether for the automotive, aerospace, tooling or consumer goods industry: with LAUFFER powder presses you produce high-quality components.

Complex geometries in metal, hard metal or ceramics, which would otherwise have to be produced at great expense, can be produced economically, quickly and efficiently. LAUFFER offers the entire portfolio from laboratory presses for material testing purposes, presses for prototype and small series production to multi-plate presses with up to 13 axes or press lines for mass production.

Since Lauffer powder presses without mechanical fixed stops position all machine axes synchronously, automatic corrections of the press position during operation are possible, efficiently and without manual intervention.

Of course, efficient automation of powder presses is also part of our portfolio. With our specially developed CNC control system and our intelligent “powder assistant” for tool development, program sequence optimization and quality assurance, you can operate and monitor every pressing process conveniently, safely and reliably.

OUR CUSTOMERS

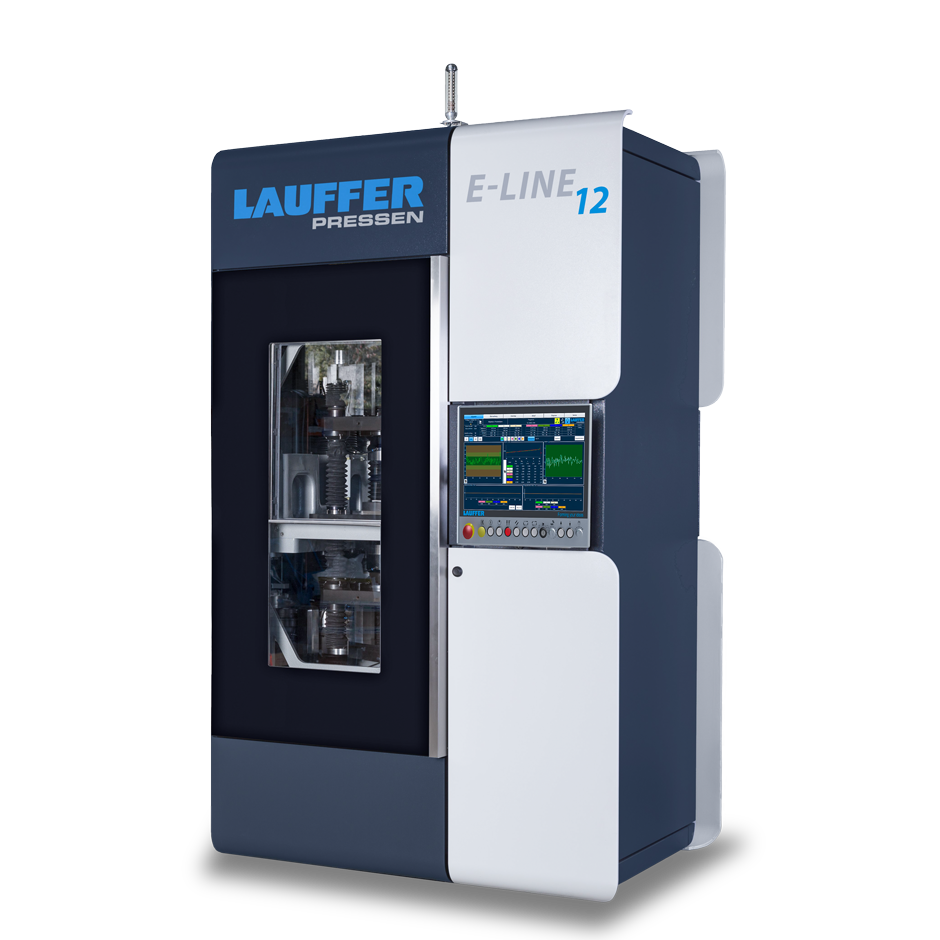

E-Line Powder Compacting Presses

Whether for the automotive, aerospace, tooling or consumer goods industry: with LAUFFER powder presses you produce high-quality components.

Complex geometries in metal, hard metal or ceramics, which would otherwise have to be produced at great expense, can be produced economically, quickly and efficiently. With LAUFFER E-Line powder presses, you can produce high-quality components particularly economically and within the narrowest tolerance fields, so that mechanical finishing is usually no longer necessary.

Since Lauffer powder presses position without mechanical fixed stops, automatic corrections of the press position during operation are possible, efficiently and without manual intervention.

Of course, efficient automation of powder presses is also part of our portfolio. With our specially developed CNC control system and our intelligent “powder assistant” for tool development, program sequence optimization and quality assurance, you can operate and monitor every pressing process conveniently, safely and reliably.

E-Line Powder Compacting Presses

Whether for the automotive, aerospace, tooling or consumer goods industry: with LAUFFER powder presses you produce high-quality components.

Complex geometries in metal, hard metal or ceramics, which would otherwise have to be produced at great expense, can be produced economically, quickly and efficiently. With LAUFFER E-Line powder presses, you can produce high-quality components particularly economically and within the narrowest tolerance fields, so that mechanical finishing is usually no longer necessary.

Since Lauffer powder presses position without mechanical fixed stops, automatic corrections of the press position during operation are possible, efficiently and without manual intervention.

Of course, efficient automation of powder presses is also part of our portfolio. With our specially developed CNC control system and our intelligent “powder assistant” for tool development, program sequence optimization and quality assurance, you can operate and monitor every pressing process conveniently, safely and reliably.

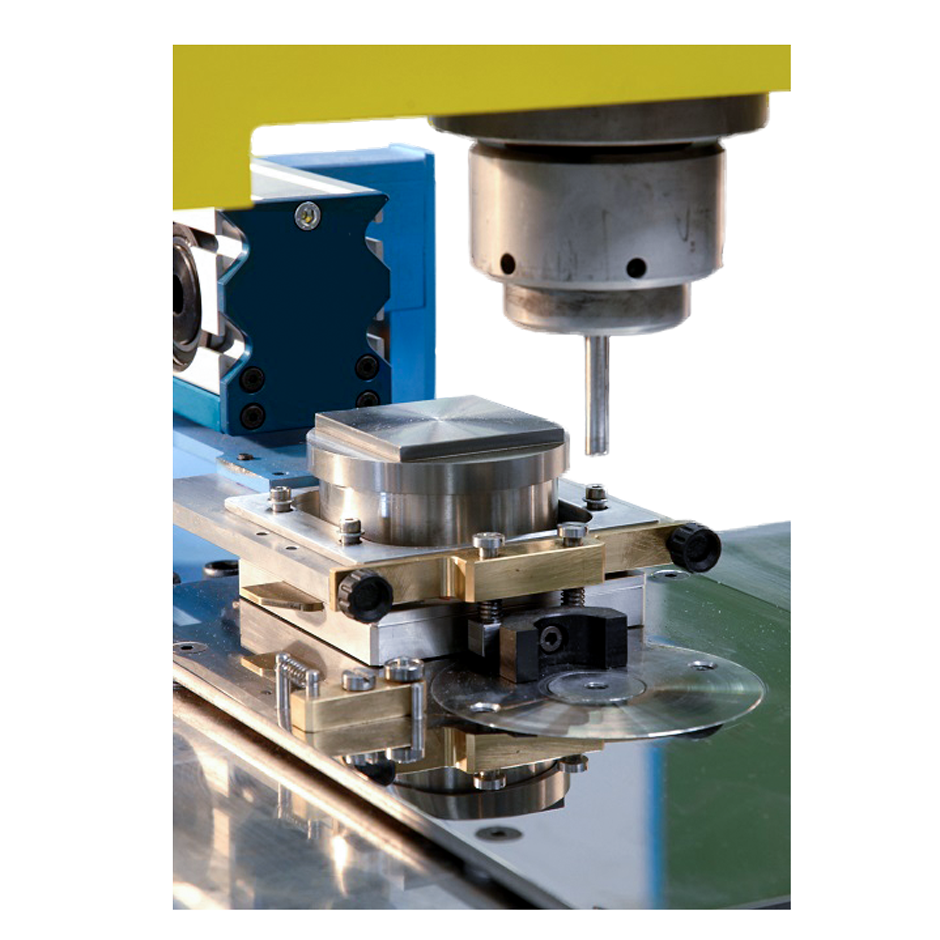

Calibration Presses

If economical reworking of component surfaces or tolerance narrowing of sintered powder metal parts is required, Lauffer offers the right solution!

Whether single press or robot automation – Lauffer offers a customized solution for your production for all parts handling tasks.

LAUFFER calibration presses offer you a number of advantages – from the highest precision of speed and force control to the constant pressure holding function throughout the entire calibration process.

CONTACT

Calibration Presses

If economical reworking of component surfaces or tolerance narrowing of sintered powder metal parts is required, Lauffer offers the right solution!

Whether single press or robot automation – Lauffer offers a customized solution for your production for all parts handling tasks.

LAUFFER calibration presses offer you a number of advantages – from the highest precision of speed and force control to the constant pressure holding function throughout the entire calibration process.

CONTACTSpecial Purpose Systems

Are you looking for a solution to an unusual problem in powder production? Our experienced engineers and technicians will support you with an optimal special solution for you.

Give us a challenge!

Special Purpose Systems

Are you looking for a solution to an unusual problem in powder production? Our experienced engineers and technicians will support you with an optimal special solution for you.

Give us a challenge!