Forming Technology

Whether sheet metal forming, massive forming or composite forming: For many decades LAUFFER has been shaping your materials with hydraulic and servo-hydraulic presses. Our press and service program offers a wide range of series and complete solutions – for the automotive and white goods industries and their suppliers as well as for the construction industry, plant and container construction and medical technology.

The advantages of chip less forming with LAUFFER presses are obvious: low unit costs through maximum productivity and availability of the presses as well as constant part quality through the reproducible pressing process. And, of course, the fast amortization through reliable technology, easy operation and fast tool changes.

LAUFFER R-Series Hydraulic frame presses for metal forming

From 630 kN to 10.000 kN freely configurable for your application. Whether forming, punching, cutting or embossing – LAUFFER’s solid and variable press frame concept allows individual adaptation of the press size to your requirements. For smaller presses in monobloc design and for larger presses or harsher conditions as tie-rod variant.

R-PT

Frame presses with column-guided ram, centric cutting shock-damping and fixed stop

R-PS

Frame presses with precise ram flat guide, centric fixed stop and cutting impact damping.

R-A

Automatic punching presses with high stroke rate

R-PN

Frame press with cutting impact damping elements between ram and table

R-ZU

Frame press for deep drawing processes with drawing device in the press bed and/or slide.

LAUFFER R-Series Hydraulic frame presses for metal forming

From 630 kN to 10.000 kN freely configurable for your application. Whether forming, punching, cutting or embossing – LAUFFER’s solid and variable press frame concept allows individual adaptation of the press size to your requirements. For smaller presses in monobloc design and for larger presses or harsher conditions as tie-rod variant.

R-PT

Frame presses with column-guided ram, centric cutting shock-damping and fixed stop

R-PS

Frame presses with precise ram flat guide, centric fixed stop and cutting impact damping.

R-A

Automatic punching presses with high stroke rate

R-PN

Frame press with cutting impact damping elements between ram and table

R-ZU

Frame press for deep drawing processes with drawing device in the press bed and/or slide.

OUR CLIENTS

Fully Automated Press Lines

Equipped with loaders, processing lines in short and long design and handling devices such as rail transfer, feeders or robots, a single press becomes an automated production cell. At LAUFFER we develop the automation concept “Front of Line” and “End of Line”, taking into account all marginal parameters and according to your requirements, integrated into a uniform control concept.

Fully Automated Press Lines

Equipped with loaders, processing lines in short and long design and handling devices such as rail transfer, feeders or robots, a single press becomes an automated production cell. At LAUFFER we develop the automation concept “Front of Line” and “End of Line”, taking into account all marginal parameters and according to your requirements, integrated into a uniform control concept.

OUR CLIENTS

Fiber-reinforced plastics

Fibre composites obtain their high-quality properties through the interaction of the individual components. And it is the same with our composites presses and automation components such as resin injection, tool temperature control and handling equipment: Only the precise interaction of all components produces the best composites.

Our RKP composite press series is suitable for large-volume components with a duromer or thermoplastic matrix. Fast closing times and/or long curing times are freely programmable. The precise and exactly parallel closing of the upper tool is made possible by the actively controlled parallel position of the ram in the range of hundredths of a millimeter – an absolute “must” for high-precision components. Whether you want to use a pure pressing technique or injection compression moulding: LAUFFER has the solution!

Fiber-reinforced plastics

Fibre composites obtain their high-quality properties through the interaction of the individual components. And it is the same with our composites presses and automation components such as resin injection, tool temperature control and handling equipment: Only the precise interaction of all components produces the best composites.

Our RKP composite press series is suitable for large-volume components with a duromer or thermoplastic matrix. Fast closing times and/or long curing times are freely programmable. The precise and exactly parallel closing of the upper tool is made possible by the actively controlled parallel position of the ram in the range of hundredths of a millimeter – an absolute “must” for high-precision components. Whether you want to use a pure pressing technique or injection compression moulding: LAUFFER has the solution!

OUR CLIENTS

Special purpose presses

In double or C-frame design, for deep drawing, embossing, bending, punching or for other special requirements.

CONTACTSpecial purpose presses

In double or C-frame design, for deep drawing, embossing, bending, punching or for other special requirements.

CONTACT

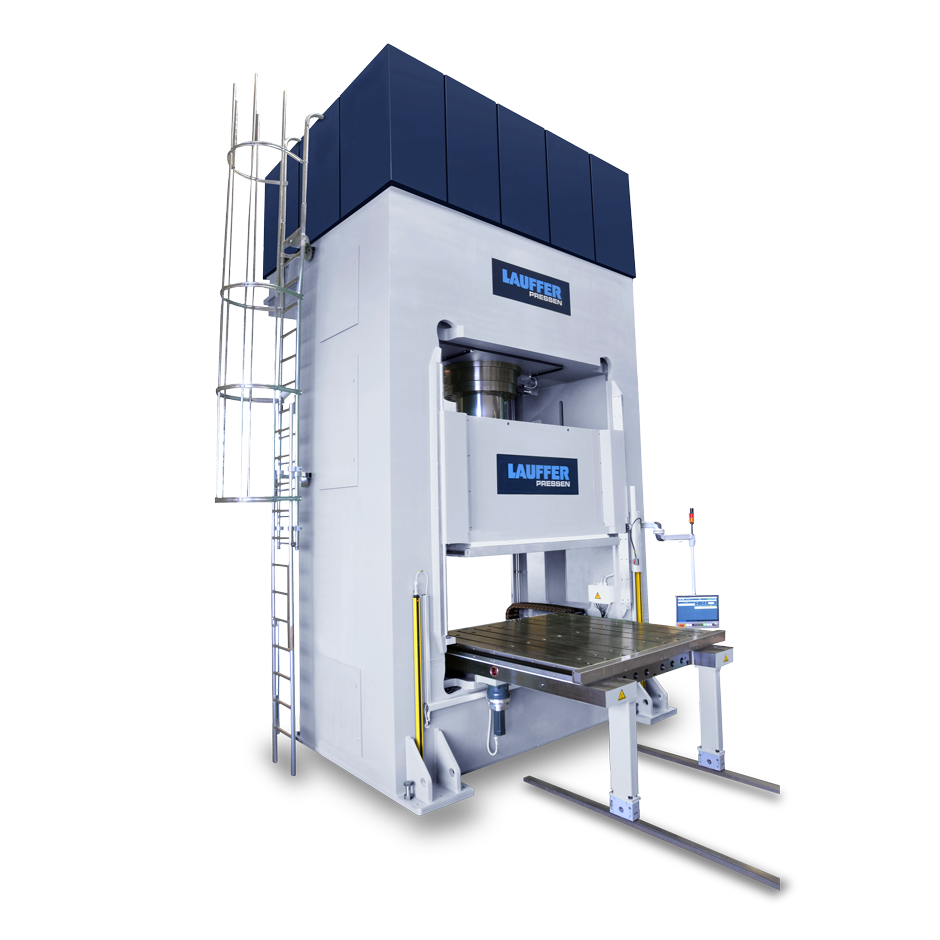

Tool try-out presses

Precise testing in tool and mould making is essential for the quality of your products. To relieve your production presses and to document the tool quality, a tool testing or tryout press is indispensable. We offer you the entire spectrum – from the simple column press to the eight-station flat-guided press with minimum deflection values and operating speeds comparable to your production presses. We realize the active parallel holding of the ram by means of controlled long-stroke or short-stroke cylinders.

OUR CLIENTS

Tool try-out presses

Precise testing in tool and mould making is essential for the quality of your products. To relieve your production presses and to document the tool quality, a tool testing or tryout press is indispensable. We offer you the entire spectrum – from the simple column press to the eight-station flat-guided press with minimum deflection values and operating speeds comparable to your production presses. We realize the active parallel holding of the ram by means of controlled long-stroke or short-stroke cylinders.

Massive forming

The cold or warm massive forming of materials requires a high force density and a large working capacity. Hydraulic forming presses from LAUFFER ensure both of these by their very rigid design. In addition, our presses make single or multi-stage processes possible, with or without mechanical fixed stops.

Massive forming

The cold or warm massive forming of materials requires a high force density and a large working capacity. Hydraulic forming presses from LAUFFER ensure both of these by their very rigid design. In addition, our presses make single or multi-stage processes possible, with or without mechanical fixed stops.