Laminating Technology

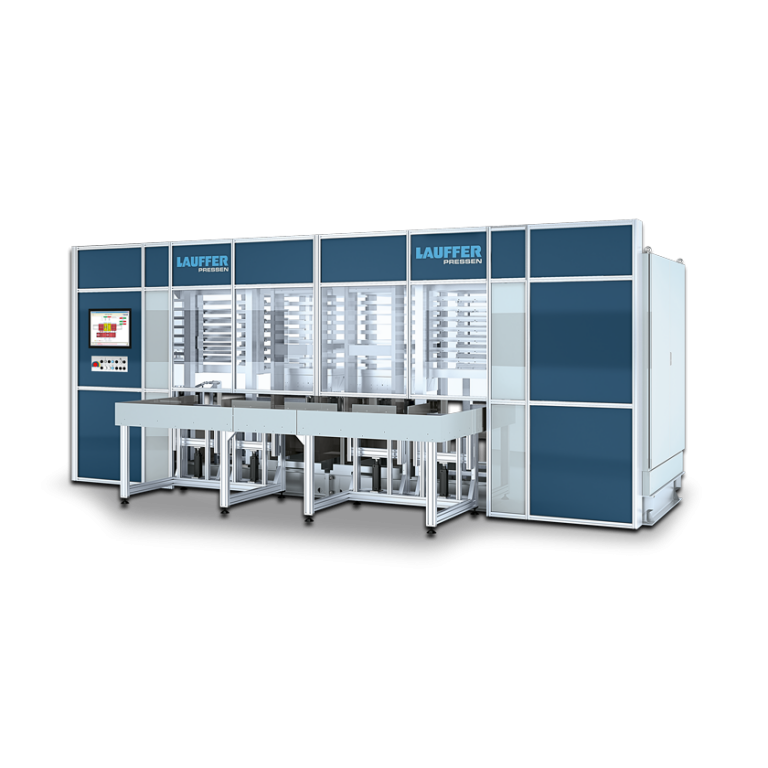

Laminating Technology from LAUFFER covers a variety of industry solutions and special applications. Whether for the production of printed circuit boards (PCBs) or base material (CCL), the lamination of smart cards, ID documents and technical laminates. All LAUFFER laminating systems offer you leading technology, highest production efficiency with maximum availability and proven durability “Made in Germany”.

From laboratory presses to manual single presses to fully automated lamination centers for mass production: our products and systems are optimally adapted to market requirements and your production. Innovative control technology and state-of-the-art heating and cooling technology also ensure efficient and flexible production.

Lamination Technology for the printed circuit board industry

LAUFFER has been one of the market leaders in the field of vacuum laminating systems for rigid and flexible printed circuit boards (PCBs), base material and special applications for decades. And for good reasons: Whether laboratory and experimental presses for material tests and process development, whether prototype and small series production or fully automated laminating systems for mass production – our technology portfolio offers you the greatest possible production flexibility through a modular design in pressure ranges from 5 – 2100 tons at process temperatures up to 500°C.

Lamination Technology for the printed circuit board industry

LAUFFER has been one of the market leaders in the field of vacuum laminating systems for rigid and flexible printed circuit boards (PCBs), base material and special applications for decades. And for good reasons: Whether laboratory and experimental presses for material tests and process development, whether prototype and small series production or fully automated laminating systems for mass production – our technology portfolio offers you the greatest possible production flexibility through a modular design in pressure ranges from 5 – 2100 tons at process temperatures up to 500°C.

OUR CUSTOMERS

Lamination technology for inlays, smart cards and identity documents

Whether ABS, PVC, PC, PET, PS, PE, PP or material mixes: With our single and twin stack systems CLC/LCL and our shorty-cycle lamination system SLS, we offer customized solutions for your production.

Lamination technology for inlays, smart cards and identity documents

Whether ABS, PVC, PC, PET, PS, PE, PP or material mixes: With our single and twin stack systems CLC/LCL and our shorty-cycle lamination system SLS, we offer customized solutions for your production.

OUR CUSTOMERS

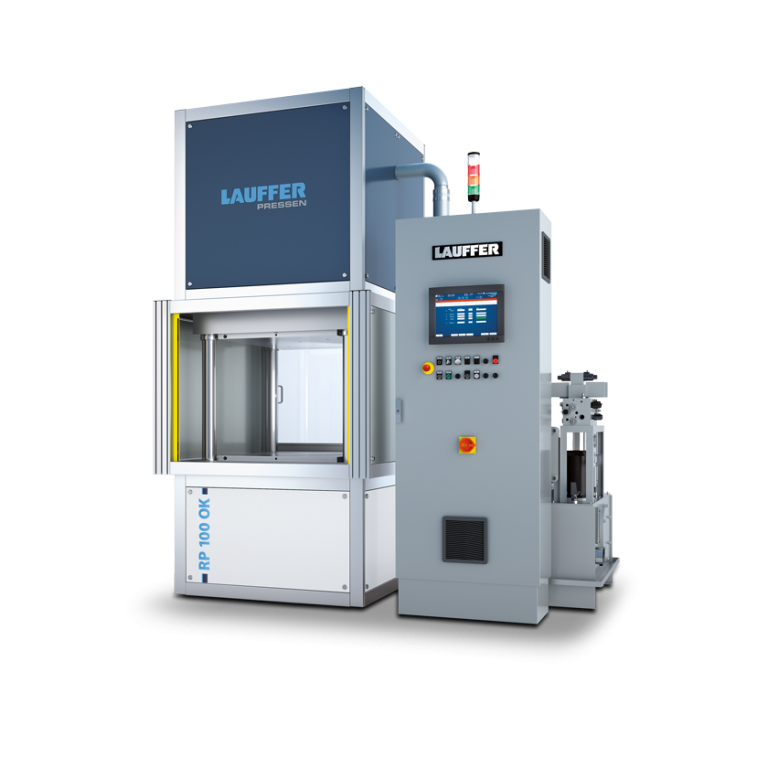

Die LAUFFER SLS (Short-cycle Lamination System)

The Lauffer press type SLS is designed for lamination of plastic cards made of PC, PVC, PET, TPU, etc. and technical laminates. This press system meets the latest requirements in terms of economy, ecology, product and process quality.

Due to the independent and stepless adjustment of the relevant process parameters such as temperature, pressure and cycle times, the system is excellently suited for large-scale production, production trials and also for product/process development – thus we can guarantee full process control for each individual sheet.

Technical Laminates

Whether fiber composites (GRP/CFRP combinations, etc.), ceramic substrates (LTCC), film lamination or medical applications: The variety of components that can be produced in lamination processes is almost unlimited. LAUFFER offers you machine concepts for demanding lamination processes which are specially adapted to your requirements: Factors such as lower and upper plunger design, heated with thermal oil or eclectically, freely selectable platen and table sizes, application of vacuum technology, to produce technical laminates even under atmospheric conditions or under vacuum.

Technical Laminates

Whether fiber composites (GRP/CFRP combinations, etc.), ceramic substrates (LTCC), film lamination or medical applications: The variety of components that can be produced in lamination processes is almost unlimited. LAUFFER offers you machine concepts for demanding lamination processes which are specially adapted to your requirements: Factors such as lower and upper plunger design, heated with thermal oil or eclectically, freely selectable platen and table sizes, application of vacuum technology, to produce technical laminates even under atmospheric conditions or under vacuum.